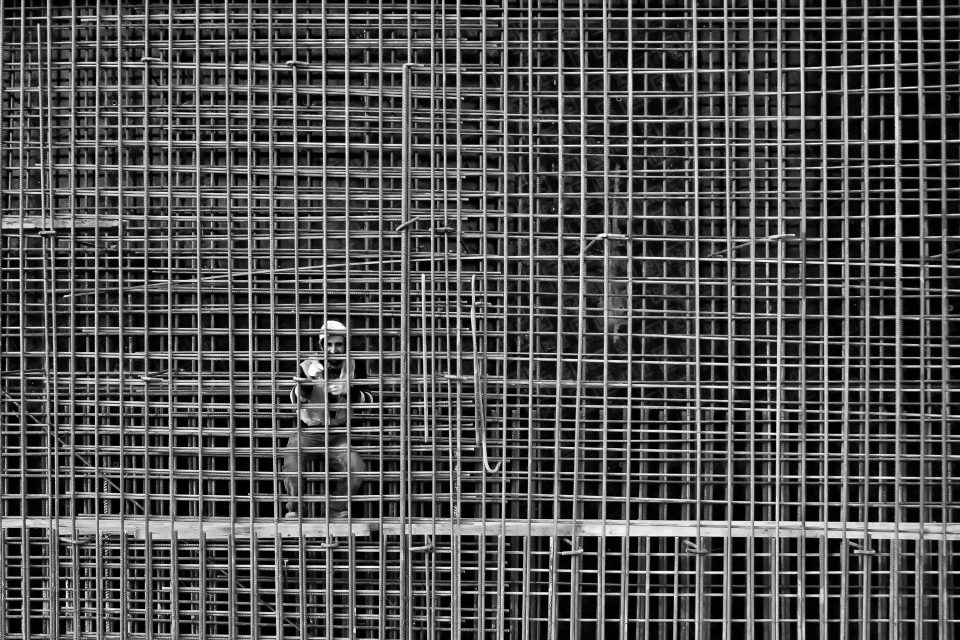

Steel reinforcement is a crucial element in construction, providing the strength and durability necessary to support buildings, bridges, and other structures. Reinforcement steel, also known as rebar, is used to reinforce concrete and other materials, providing tensile strength and preventing the form from cracking or collapsing under pressure.

One of the most dependable and popular building materials available is concrete. Projects rely on steel reinforcement for its strength and binding capabilities, which you can achieve using readily available materials. Due to its versatility may be used almost anywhere, from simple parking lot columns to wide-span bridges.

However, in this situation, various forms of steel reinforcement are used because concrete alone is not an effective structural material. Due to their improved resistance to harsh temperatures, these finished steel products enhance the value of concrete constructions.

However, not all steel reinforcement is created equal, and various types of steel reinforcement are available to suit different construction needs. Every kind of reinforcement has unique properties and benefits, making choosing the right style for a specific construction project essential.

Mild steel rebar is a prominent type of steel reinforcement in construction projects because it is accessible, adaptable, and made from carbon steel. It is a well-liked option for various applications because it is easy to weld, cut, and bend into the desired shape.

The choice of steel reinforcement for a building project will depend on its specific requirements. Cost, strength, and durability are further factors that affect the decision. Architects, engineers, and construction professionals may make well-informed decisions.

Moreover, it guarantees that their structures are built to last by being aware of the various types of steel reinforcement available. Continue reading this article to learn more about steel reinforcements and multiple classifications.

How does Steel Reinforcement Work?

Builders mix primary concrete or cement with quickly made steel bars throughout the construction approach. As already established, when used alone, concrete tends to be fragile. It is dangerous for buildings since it is unstable under high-impact conditions and heavy loads.

Including steel reinforcing bars or rebars improves the tension and compression of the material. By enhancing the tensile property of the concrete, these reinforcing bars help to lessen internal tensions and pressure-related fissures.

There are various kinds of steel reinforcing bars, and each has characteristics that set it apart from the others. These consist of prestressing steel bars, mild steel bars, deformed bars, and hot-rolled and cold-rolled steel bars, respectively. The production process, as well as flexibility and tensile strength, varies.

Deformed Hot Rolled Bars

The process of subjecting steel materials to extremely high temperatures exceeding the recrystallization rate is known as “hot rolling.” which, for steel, ranges from 400 to 700 degrees. Deformed steel bars become much easier to work with and bend at this pace of heating because they become more malleable and machinable.

A billet, which is a rectangular, pre-finished steel bar, acts as the base in the production of hot-rolled deformed bars. After heating the billet in chambers, builders roll it through a machine to construct a thin sheet metal roll. Swiftly rotating rollers press the highly warmed steel strand to form the hot-rolled deformed bars.

Bars of Cold-Rolled Steel

Manufacturers view cold rolling, also known as hard finishing, as the second process in fabricating steel bars tracking hot rolling or hot working. They always apply heat and other heat treatment processes in manufacturing any cold-rolled steel reinforced bar.

Moreover, an apparent reduction of internal tensions in the material is one benefit of cold-rolled steel bars. Remember that heating steel improves its overall strength and characteristics. It can also result in increased metallurgical stresses, which can cause cracks and surface deformations.

However, the cold-rolled steel bar will have significantly higher dimensional tolerances. If cooled to room temperature, the steel reinforcement can undergo a capacity of surface treatments.

Cold-rolled steel offers a significantly higher tensile strength when compared to hot-rolled reinforcing bars, which are more flexible and workable. It is due to the absence of plastic yield, which reduces mobility while significantly boosting resistance to crack development.

Steel Bars for Prestressing

Manufacturers use strands or tendons to make steel bars for prestressing or prestressed structures. Prestressing introduces high compression rates into the concrete before subjecting it to any state of the load.

Builders construct prestressed steel bars to provide opposing forces once the construction is complete, a process is known as post-tensioning. It compensates for any stresses created by loads, enabling the concrete to stay in compression and lowering the likelihood of cracks.

When cut, prestressing steel has a circular cross-section, similar to various reinforcement steel bars. The strand must be heat treated by tempering, stretching, and annealing in addition to the initial hot rolling procedure used to make this product to increase its tensile strength. Prestressed bars can endure more significant pressures than hot-rolled steel can, up to 270000 psi.

Mild Steel Bars

Reinforcing bars made of mild steel lack distinctive surface ribs or threads. Carbon comprises less than 0.25% of the steel in this category, and there are no other traces of alloying components present.

Contrary to its medium and high-carbon counterparts, mild steel bars have limited yield strength and little corrosion resistance, even though this makes the steel more machinable.

Mild steel bars, however, are once more a sensible choice for little building tasks. They are less expensive to produce and a cost-effective solution for constructing projects on a tight budget because they don’t require further processing.

Key Takeaway

Each type of steel reinforcement has distinct qualities and advantages of its own. The choice of reinforcement steel will depend on the specific needs of a construction project, considering factors such as cost, strength, and durability.

Understanding the different types of steel reinforcement available is crucial for architects, engineers, and builders to make informed decisions. Moreover, this is to ensure that their structures will last long built to last.